Unless you are dealing with generic common design cases, I reckon this question would always pop up on almost all designers when they are dealing with STM. As I mentioned briefly in my previous post on the Principles of Strut-and-Tie Modelling, the design of a concrete member by using STM usually involves the estimation of an initial size, finding an appropriate STM model, and dimensioning struts, ties and nodes. STM is a lower bound theorem of plasticity design method. In each load cases, there are more than one admissible STM model can be developed as long as each model satisfies internal force equilibrium and met the stress limit defined in the code (material strength). In reality, only few viable model is possible because of the limited ductility in the structural concrete.

Developing an appropriate STM for a complex concrete member is perhaps the most challenging task in the design process. STM design method involve a trial-and-error iterative approach based on the designer’s intuition and previous experience. Schlaich et al. (1987) suggested that the most appropriate STM model should inline within ±15º from the main directions of the principal elastic stress fields. This approach is to ensure that both serviceability and ultimate limit states can be satisfied. Furthermore allows the element to sustain the loads with least cracking and least plastic deformation.

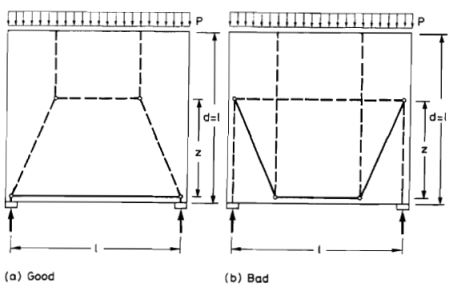

Doubts could arise as to whether the correct model has been chosen. For instance in the case as shown in Figure 1, where both models are considered as valid model. After extensive studies with multiple STM models, Schlaich et al. (1987) suggested that the STM models with the minimum strain energy constitute the most appropriate model. The minimum strain energy criterion for optimizing a model can be defined as follows:

U = ∑ Ti Li εi = minimum

It should be noted that loads always try to use the path with the least forces and deformations. Since reinforcement ties are much more deformable than concrete struts, the contribution of the concrete struts are usually omitted in the calculation of the strain energy. The model with the least and shortest tie is the best.

Due to difficulties in developing an appropriate STM model and to improve its efficiency, the application of evolutionary structural optimization (ESO) procedure has received considerable attention over the years as an alternative approach (Liang et al. (2000)). ESO is a simple and straightforward method that involves systematically removing redundant elements from discretized concrete member to achieve an optimal design. The actual load paths within the concrete member can be characterized by the remaining elements. The optimal topology of a plane stress continuum structure produced by ESO often had a truss-like structure layout, which make it highly appropriate to apply this technique in finding the optimal STM model in reinforced concrete structures. Few of the examples obtained from Liang et al. (2000) paper are illustrated in Figure 2-4.

AStrutTie is an automatic design/analysis software for strut-and-tie modelling. It integrated with a very powerful and advanced feature of evolutionary structural optimization technique, which enable structural designers to find the optimal STM models in any complex cases.

Watch the video below to find out more on the Evolutionary Structural Optimization feature in AStrutTie.

Reference

- Schlaich J., Schäfer K. and Jennewein M., “Toward a Consistent Design of Structural Concrete”, PCI Journal, Vol. 32, No. 3, May-June 1987, pp. 74-150.

- Liang Q. Q., Xie Y. M. and Steven G. P., “Topology Optimization of Strut-and-Tie Models in Reinforced Concrete Structures Using an Evolutionary Procedure”, ACI Structural Journal, Vol. 97, No. 2, March-April 2000, pp. 322-330.